Product designer Eri

News date : 2019 - 09 - 29

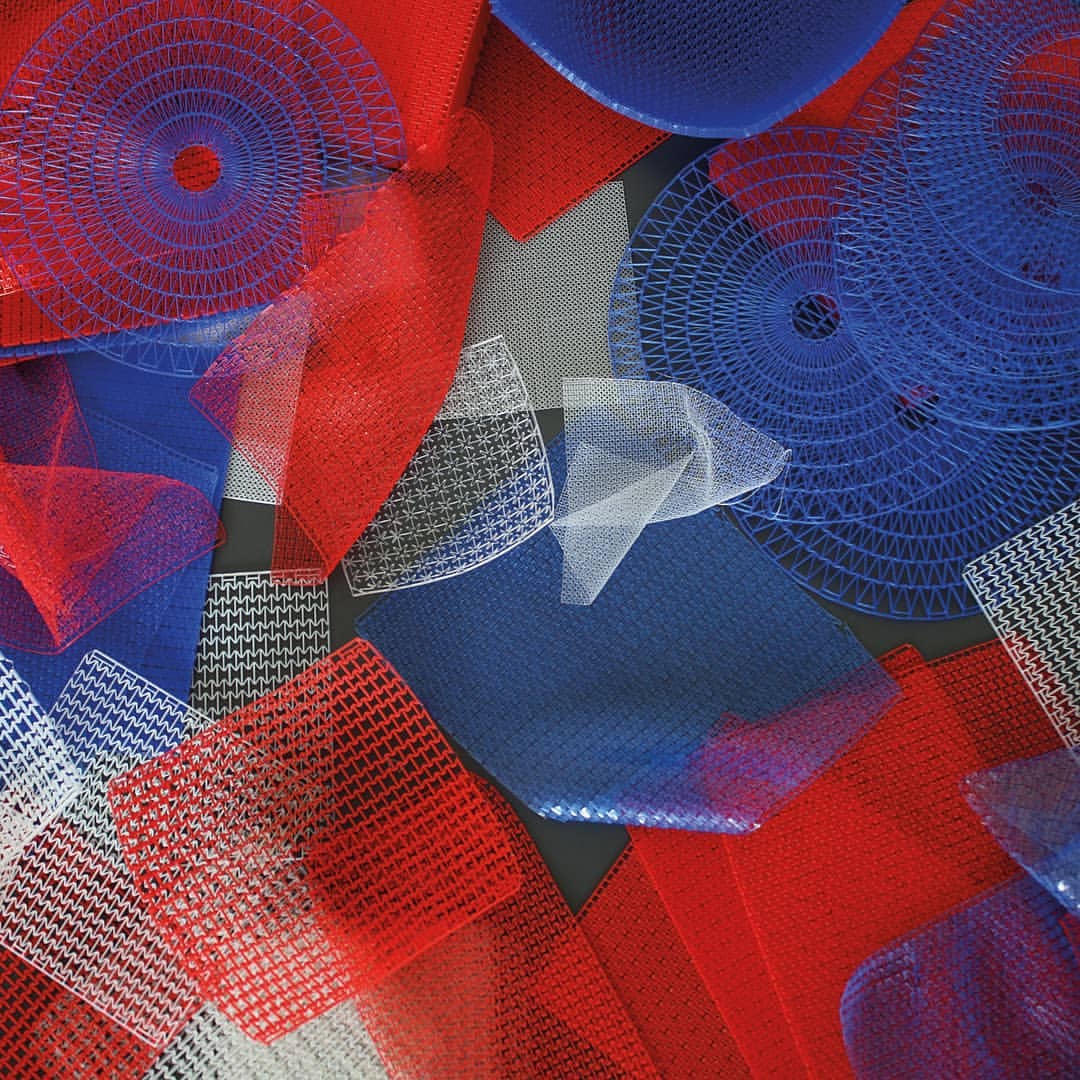

Product designer Eric Esser is pushing the limits of additive manufacturing, processes where

components are produced by depositing materials layer by layer, also known as 3D printing. In his MA thesis Esser generated CAD files that result in material samples by means of a 3D printing method called Fused Deposition Modelling (FDM). In terms of refinement these soft and supple printed results can compete with fine woven textiles. Esser employs a similar technology for Pheres, an extremely lightweight and elastic plastic shoe. The decisive feature here is the printed texture that lends both shoe upper and sole elasticity and which fits the foot like a second skin. 3D printing makes it possible to customise products to the wearers’ needs, manufactured without seams or the use of glue it can be returned to the production cycle after use.

Presented at The Sustainable Innovations Forum

.

.

.

#3Dprinting #newmaterials #susinns #sustainablefashion #sustainableinnovations #keyhouse #productlife #manufacturing #designer #collaborate #munique #munichfabricstart @simonangelmfs