Boost Your Paper Quality with Next-Gen Polyester Forming Fabrics at Paper Eurasia 2026

News date : 2025 - 12 - 24Zeinab Zare'

Advances in Polyester Forming Fabrics Highlighted Ahead of Paper Eurasia Expo 2026

As the Paper Eurasia Expo 2026 approaches, industry experts are drawing attention to innovations in polyester forming fabrics, which play a crucial role in determining paper quality and machine efficiency.

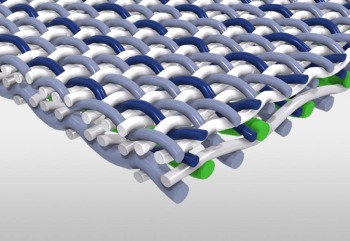

The selection of forming fabrics often depends on mesh count, which influences the fabric’s texture and structural characteristics. Single-layer fabrics with a two-shed weave, for example, offer solid mechanical properties and dimensional stability while resisting mechanical damage. However, the smaller curvature radius of the mesh threads tends to reduce surface smoothness, making this type more suitable for paperboard production.

In contrast, four-shed weaves featuring a 3-over-1 pattern provide a smoother, more uniform surface. The arrangement of the mesh threads minimizes straight-line textures, leading to lighter fabric marks, lower loss of fine fibers, and strong drainage capacity. These properties make four-shed fabrics suitable for a wide range of paper grades, including newsprint, offset printing paper, high-grade chemical pulp paper, and supercalendered printing paper.

Double-layer fabrics, such as 7-shed and 8-shed constructions, are more complex to manufacture but combine a smooth, uniform surface with high mechanical strength and dimensional stability. These fabrics are commonly used for high-grade printing paper and tissue paper production across various types of paper machines.

Among the most widely used products in today’s market are 16-shed two-and-a-half-layer forming fabrics, as well as 20-shed and 24-shed triple-layer SSB (Sheet Support Binder) fabrics, which continue to meet the performance demands of modern paper production.

The upcoming Paper Eurasia Expo offers an opportunity for manufacturers and paper producers to explore these materials and assess their impact on production efficiency and paper quality.